In today’s fast-evolving world of digital transformation, new technologies are reshaping industries across the globe. One such game-changing technology is Digital Twin Technology. It has emerged as a vital innovation, offering companies the ability to simulate, monitor, and optimize real-world systems virtually. In this comprehensive guide, we will explore digital twin technology, its working, applications, benefits, and how it is transforming industries like manufacturing, healthcare, and logistics.

What is Digital Twin Technology?

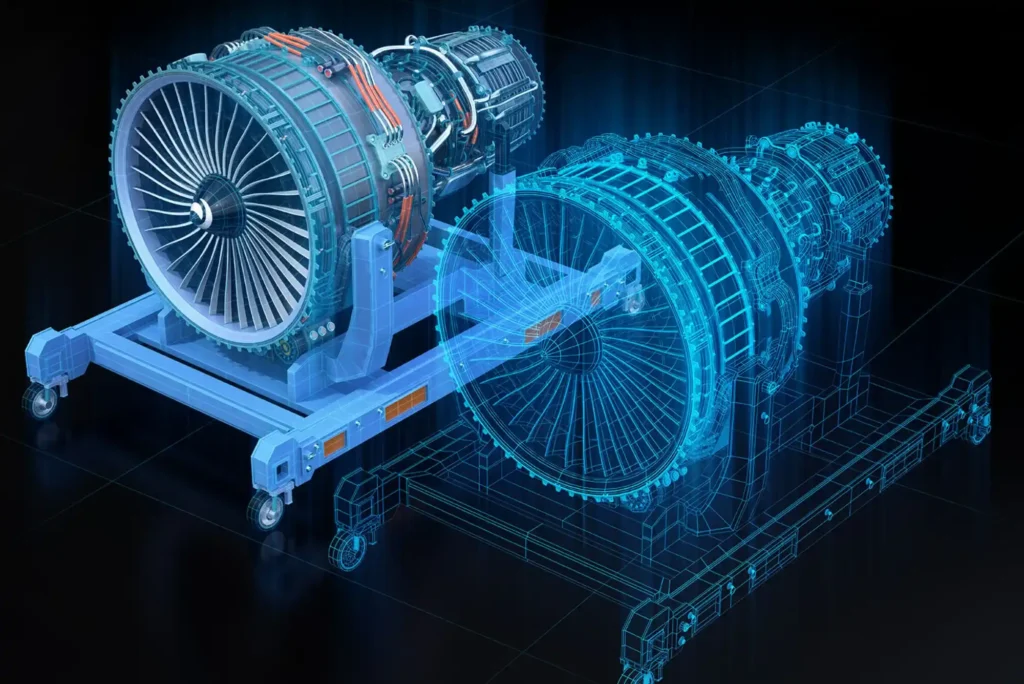

At its core, digital twin technology refers to the virtual representation or digital replica of a physical asset, system, or process. The digital twin acts as a mirror that captures real-time data and uses it to create a dynamic model of the object, allowing engineers, operators, and analysts to monitor performance, identify potential issues, and improve efficiency through data-driven decisions. The primary goal is to create a seamless connection between the physical and digital worlds.

Digital twins are widely used to predict failures, test scenarios, and optimize performance by gathering information from sensors, IoT devices, and other connected technologies. This technology integrates machine learning (ML), artificial intelligence (AI), and big data analytics to enable continuous monitoring and simulation of a physical entity’s operation throughout its lifecycle.

How Digital Twin Technology Works

The process of creating and maintaining a digital twin involves multiple stages:

- Data Collection: Sensors and IoT devices installed on physical assets gather real-time data, such as temperature, pressure, performance metrics, and environmental conditions.

- Model Creation: The collected data is fed into a virtual model, creating a digital replica of the physical asset. Advanced algorithms and analytics are used to simulate its behavior.

- Simulation and Monitoring: Once the digital twin is created, it constantly updates with real-time data from the physical world. This simulation enables predictive analysis and proactive decision-making.

- Optimization and Insights: Through continuous feedback loops, the digital twin can suggest optimizations and alert stakeholders about potential malfunctions or maintenance needs.

Digital twins can range from simple models of individual components to highly complex systems involving entire factories or cities.

Types of Digital Twins

There are different types of digital twins based on the level of integration and scope of the system being modeled:

| Type | Description |

|---|---|

| Component Twin | Focuses on modeling a specific part or component of a system, enabling detailed analysis of its performance and behavior. |

| Asset Twin | Simulates an entire asset (e.g., machine or equipment) to provide insights into its overall functionality, performance, and operational health. |

| System Twin | Covers a broader scope by modeling an entire system or network of interconnected assets, allowing for improved system-level decision-making and optimization. |

| Process Twin | Models entire workflows or business processes to understand inefficiencies, bottlenecks, and opportunities for improvement across operations. |

Key Industries Adopting Digital Twin Technology

Manufacturing

Manufacturing is one of the leading industries benefiting from digital twin technology. By creating virtual replicas of production lines, factories, and individual machines, manufacturers can monitor equipment health, predict downtime, and optimize production processes. This results in increased efficiency, reduced costs, and improved product quality.

For example, digital twins can simulate different scenarios for optimizing plant layouts, minimizing material waste, and testing new designs before they are implemented in the real world. Additionally, it enables predictive maintenance, ensuring that potential failures are addressed before they occur, thereby reducing unplanned downtime.

Healthcare

In healthcare, digital twin technology is used to create virtual models of human organs, patients, and healthcare systems. These digital replicas allow doctors and medical professionals to personalize treatment plans, simulate surgeries, and track patient recovery in real time.

For instance, medical device manufacturers can create digital twins of their products, enabling them to monitor usage and performance. Hospitals can use digital twins to simulate the flow of patients, staff, and resources to improve hospital operations and reduce patient wait times.

Transportation and Logistics

Transportation and logistics companies are increasingly adopting digital twin technology to optimize supply chains, vehicle performance, and route planning. By using digital replicas of fleets, warehouses, and logistics operations, companies can gain real-time insights into delivery performance, vehicle maintenance needs, and inventory management.

For example, digital twins can help logistics firms optimize routes by analyzing traffic patterns, weather conditions, and fuel consumption. This leads to cost savings, improved delivery times, and enhanced customer satisfaction.

Smart Cities

Digital twins are also playing a vital role in the development of smart cities. City planners can use digital twin technology to simulate infrastructure systems, energy consumption, and urban mobility, allowing them to optimize resource usage and improve sustainability.

By modeling entire cities, authorities can monitor the performance of utilities like electricity, water, and waste management, as well as track traffic patterns and pollution levels in real time. This information helps improve the quality of life for residents and ensures that cities operate efficiently and sustainably.

Benefits of Digital Twin Technology

There are several key advantages to using digital twin technology across industries:

Improved Operational Efficiency

By providing real-time insights into the performance of assets, digital twins allow businesses to optimize operations and make data-driven decisions. Companies can identify inefficiencies, reduce downtime, and improve resource allocation, leading to significant cost savings and increased productivity.

Predictive Maintenance

One of the primary applications of digital twin technology is in predictive maintenance. By continuously monitoring asset performance, digital twins can detect early signs of wear and tear, allowing businesses to perform maintenance before failures occur. This reduces unplanned downtime, lowers repair costs, and extends the lifespan of equipment.

Enhanced Product Design and Development

In product design and development, digital twins enable companies to test and validate new designs virtually before building physical prototypes. This speeds up the development process, reduces design flaws, and minimizes the risk of costly mistakes.

Personalized Customer Experiences

In industries such as healthcare and retail, digital twin technology enables the creation of personalized experiences by simulating individual customer preferences and behaviors. This can lead to tailored products and services, improved customer satisfaction, and increased loyalty.

Risk Management

By using digital twins to simulate different scenarios, companies can assess potential risks and develop contingency plans to mitigate them. This is particularly important in industries like construction, where safety risks are high, or in supply chains, where disruptions can have a significant impact.

Challenges and Limitations

While digital twin technology offers numerous benefits, it is not without its challenges. Some of the key limitations include:

High Initial Costs

Implementing digital twin technology requires a significant upfront investment in sensors, IoT infrastructure, and software platforms. For smaller companies, these costs may be prohibitive, limiting their ability to adopt the technology.

Data Security and Privacy

Since digital twins rely on real-time data from physical assets, ensuring the security and privacy of this data is crucial. Companies must invest in robust cybersecurity measures to protect their systems from breaches and unauthorized access.

Complexity

Building and maintaining digital twins can be complex, particularly for large-scale systems that involve multiple interconnected assets. Managing and interpreting the vast amounts of data generated by digital twins requires advanced analytics capabilities and skilled personnel.

Integration with Legacy Systems

Many companies still rely on legacy systems that may not be compatible with modern digital twin platforms. Integrating these older systems with digital twin technology can be challenging and may require significant upgrades.

Future Trends in Digital Twin Technology

The future of digital twin technology is bright, with several key trends expected to drive its growth and adoption:

- AI and Machine Learning Integration: As AI and ML technologies continue to advance, they will further enhance the capabilities of digital twins, enabling more accurate simulations and predictions.

- Edge Computing: The rise of edge computing will allow digital twins to process data closer to the source, reducing latency and enabling real-time decision-making in remote locations.

- 5G Connectivity: The widespread deployment of 5G networks will provide the high-speed, low-latency connectivity required to support the real-time data transmission needed for complex digital twin applications.

FAQs

What is a digital twin used for?

A digital twin is used to create a virtual replica of physical assets, processes, or systems. It helps in monitoring performance, optimizing operations, predicting failures, and improving decision-making.

Which industries benefit from digital twin technology?

Industries such as manufacturing, healthcare, transportation, logistics, and smart cities are the main beneficiaries of digital twin technology. It helps optimize processes, reduce costs, and enhance efficiency.

What are the benefits of using digital twin technology?

The key benefits include improved operational efficiency, predictive maintenance, enhanced product design, personalized customer experiences, and risk management.

How does digital twin technology work?

Digital twin technology works by collecting real-time data from physical assets, creating a virtual model, and continuously simulating and optimizing the asset’s performance through data analysis.

Is digital twin technology expensive to implement?

Yes, the initial implementation of digital twin technology can be costly due to the need for sensors, IoT infrastructure, and advanced software. However, the long-term benefits often outweigh the costs.

Digital twin technology is rapidly transforming industries, providing real-time insights that lead to improved performance, reduced costs, and better decision-making. From manufacturing and healthcare to smart cities and logistics, the potential of digital twin technology is immense, and its future looks promising as new advancements in AI, ML, and connectivity continue to emerge.